KM70 Railway Coal Hopper Wagon 70T Air Control Bottom Doors

- Category: Railway Hopper Wagon

- Model: KM70

- Rail Gauge:1435mm

- Volume: 75m³

- Pay load: 70 tons

KM70 Railway Coal Hopper Wagon 70T Air Control Bottom Doors

1. Application

KM70 is suitable for operating on standard gauge rail lines and is used for transporting bulk goods such as coal and ore. It can meet the requirements of fixed grouping, circular use, fixed-point loading and unloading, and large-scale transportation by railway. It is widely applied in power plants, ports, Coal Company, steel and other enterprises. This hopper wagon is adapt to transmission device of material receiving pit like coal unloading trenches or high stack platforms with sufficient capacity for simultaneous unloading of coal on both sides of the railway. It can be unloaded automatically and quickly, and can also be manually unloaded in the absence of air sources.

2. Main structures

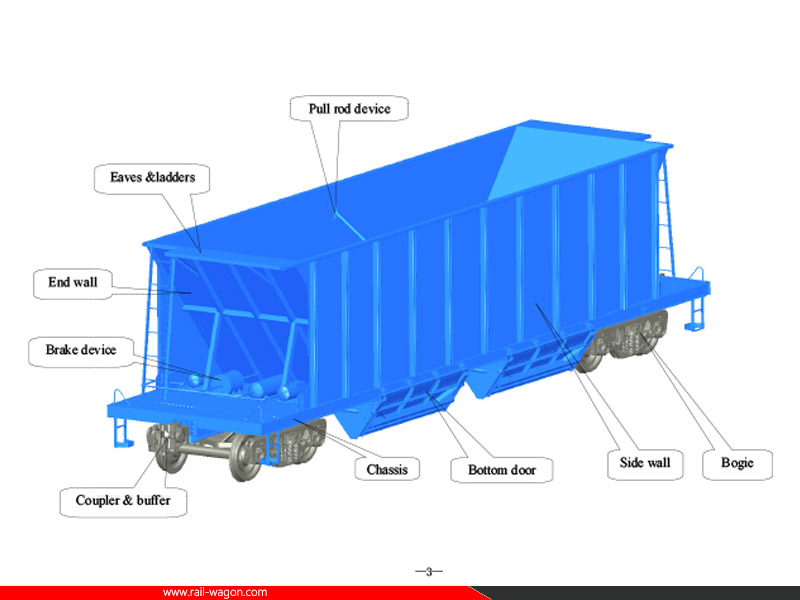

KM70 hopper wagon is mainly composed of wagon body, bottom doors opening and closing device, Air pipe line device, coupler draft gear, brake device and bogies.

-

Wagon body

The wagon body is a fully welded steel structure, consisting of a chassis, side walls, end walls, funnels, eaves and escalators, bottom doors, and tie rods. The main steel sections and plates are made of Q450NQR1 high-strength weathering steel according to Chinese railway standards.

-

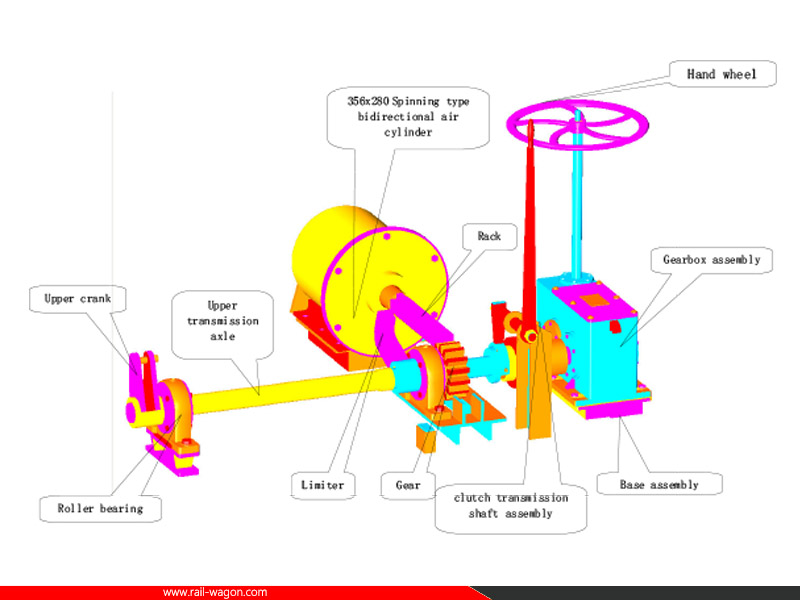

Bottom door opening and closing mechanism:

It adopts two-stage transmission and two-stage locking top lock bottom door opening and closing device. It mainly consists of an upper transmission device and a lower transmission device.

The upper transmission device mainly consists of: upper transmission shaft, toothed clutch, rolling bearings, gears, limiters, upper crankshaft, clutch transmission shaft, reducer, 356mm × 280mm spinning type bidirectional action air cylinder, rack, roller, pressure pin seat, handwheel, gear cover, etc.

The lower transmission device mainly consists of: a lower transmission shaft, lower bearings, double levers, long top rods, short top rods, couplings, connecting rods, left and right locking bodies, and lower cranks.

-

Air control unloading pipe line:

The air pipeline device consists of a supply air adjustment valve, a control valve, a cut-off plug valve, an air storage reservoir, a control panel, an air gauge, etc. The air source comes from the train main pipe and is filled into the air reservoir through the cut-off valve and the air supply adjustment valve, serving as the power source for the pneumatic opening of the bottom door. The opening and closing of the four bottom doors on both sides are controlled by a spinning type bi-directional air cylinder with a diameter of 356 mm × 280 mm during air control unloading process.

-

Air brake device

-

Hand brake machine

-

Coupler & buffer

-

Bogie

The bogie adopts K6 type cast steel three piece wagon bogie with a 23.5t axle load. The bolster and side frame are made of B-grade steel with a wide guide frame structure for the side. There is a cross support device between the two side frames. The bolster spring is of two-level rigidity.

3. Main technical parameters:

Pay

load

70t

Tare

weight

≤23.8

t

Capacity

75

m3

Axle

load

23t

Gauge

1435mm

Coupler

type

#17

coupler and MT-2 buffer

Coupler

center height(empty)

880

mm

Length

14400

mm

Bogie

type

K6

three big piece casting steel bogie

Fixed

axle distance

1830mm

Wheel

diameter

840mm

Load

method

Upper

load, bottom and sides unload

Number

of unload hatches

4

Bottom

door length

2800mm

Bottom

door opening width

460mm

Brake

method

Air

brake

Brake

distance

≤1400 m

Brake

ratio

7.8

Transmission

type

Two

stage transmission and top lock mechanism

Max.

running speed

120

km/h

Min

radius

145m

Lifespan

25

years

Limit

gauge

Comply

with GB146 1-83 ‘standard gauge railway rolling stock gauge’

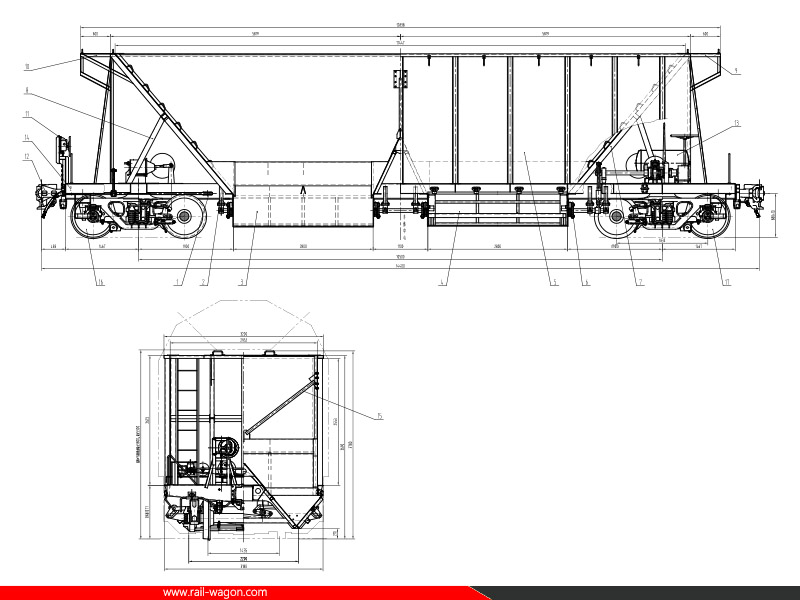

4. Drawing

5. Detail Photo

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431