Quick Unloading Coal Hopper Wagon Auto Air Control Bottom Doors 70T Pay Load

- Category: Railway Hopper Wagon

- Model: KMF70

- Rail Gauge:1435mm

- Volume: 77m³

- Pay load: 70 tons

Quick Unloading Coal Hopper Wagon Auto Air Control Bottom Doors 70T Pay Load

1. Application

KMF72 coal hopper wagon is upgraded on KM70 coal hopper wagon by adding one set air control device to open and close the bottom doors. This device could allow one rack coal wagons open and close the discharge bottom doors at the same time, which greatly improve the unloading efficiency.

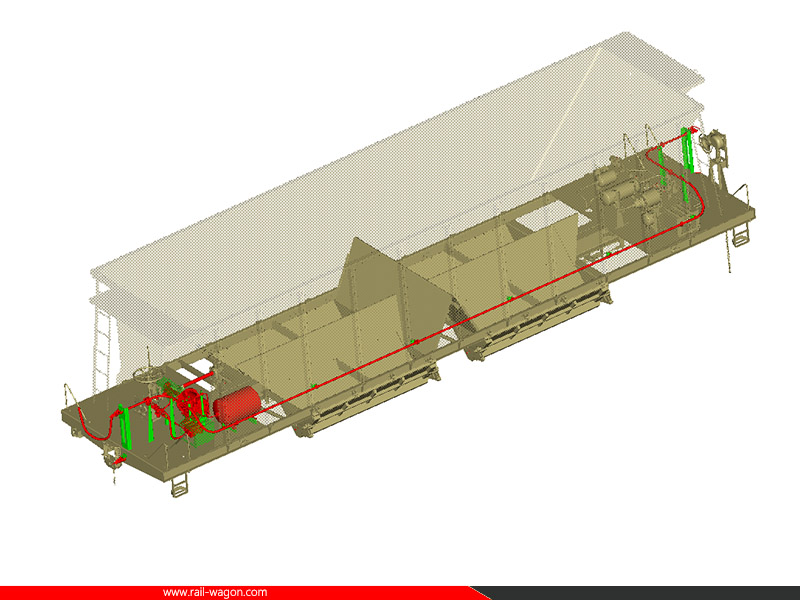

2. Additonal bottom door air control device

The added air control device is arranged on the upper part of the traction beam at the position two end of the hopper wagon. To ensure driving safety and not affecting the original air brake system, an independent train pipeline is installed to supply air to the air control unloading device. The air source of the added unloading device could be from locomotive or ground air source. An appropriate length or braided brake hose assembly is installed at the end of the wagon to connect with the air supply.

The air control device mainly includes 120 type air control valve (in order to increase the speed of filling and exhausting air, 14 inches can be used), 356×280 rotary two-way air cylinder, 160 liter air storage reservoir (stainless steel), as well as angle plug gate, combined dust collector, cut-off plug gate, braided brake soft assembly and air pressure gauge, main pipe tee, branch pipe tee, pipe fittings and corresponding pipe hangers. In order to realize the air control function and connect well with the original vehicle operating mechanism and transmission mechanism, add gear and rack transmission devices, and replace the transmission shaft and related accessories.

3. Main technical parameters:

Application

Transport bulk coals by railroad

Pay load

72t

Tare weight

24.7 t

Capacity

77 m3

Axle load

25t

Gauge

1435mm

Coupler type

No. 17 coupler and MT-2 draft gear

Coupler center height(empty)

880 mm

Length

14300 mm

Bogie type

K6 three big piece casting steel bogie

Fixed axle distance

1830mm

Wheel diameter

840mm

Load method

Upper load, bottom and sides unload

Number of unload hatches

4

Brake method

Air brake

Brake distance

≤1400 m

Brake ratio

7.8

Transmission type

Two stage transmission and top lock

mechanism

Max. running speed

120 km/h

Min radius

145m

Lifespan

25 years

Limit gauge

Comply with GB146 1-83 ‘standard gauge

railway rolling stock gauge’

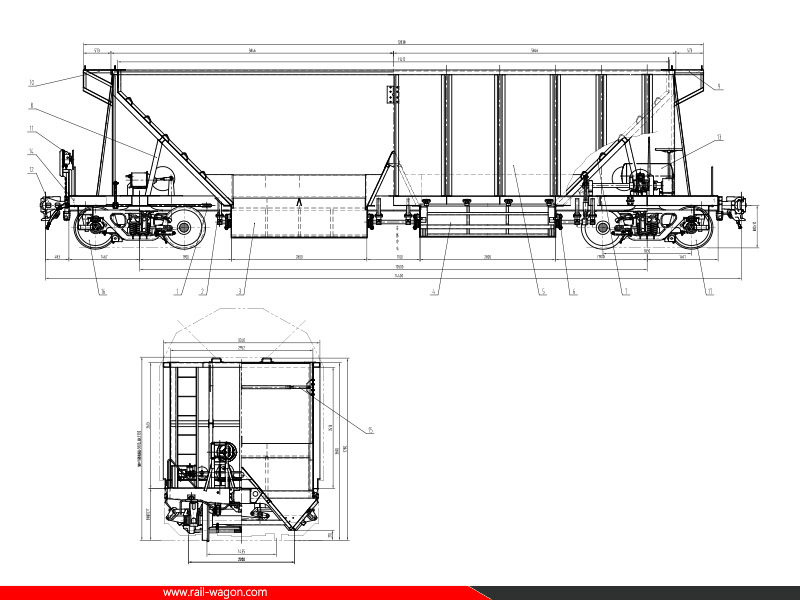

4. Drawing

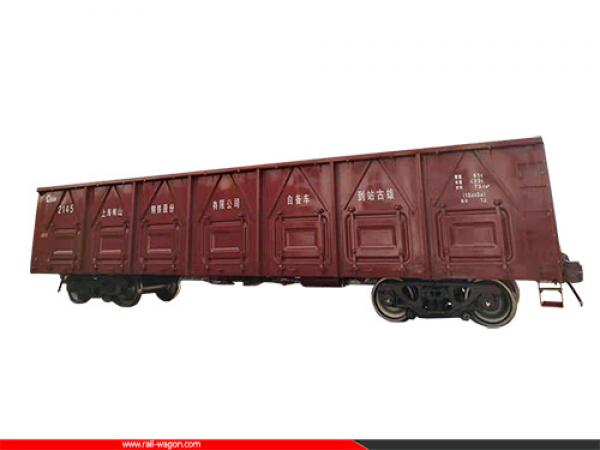

5. Detail Photo

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431