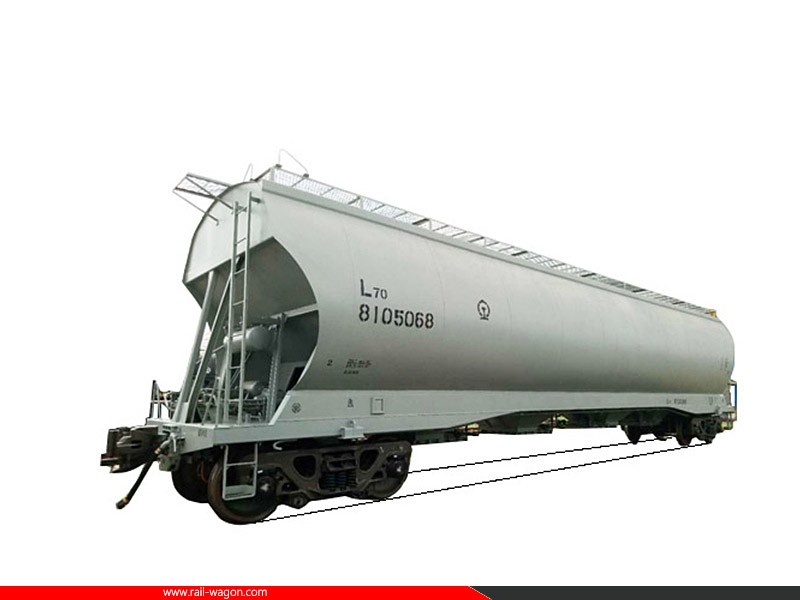

L70 Grain Hopper Wagons 70T Pay Load Corn Wheat Soybeans Railway Transport Wagons

- Category: Railway Hopper Wagon

- Model: L70

- Rail Gauge:1435mm

- Volume: 102m³

- Pay load: 70 tons

L70 Grain Hopper Wagons 70T Pay Load Corn Wheat Soybeans Railway Transport Wagons

1. Application

L70 grain hopper wagons is used on Chinese standard gauge railway lines to transport bulk grain goods such as corn, wheat, soybeans, etc. The grains are loaded from the top and unloaded from the bottom.

This hopper wagon has good adaptability to mechanized conveying and warehousing system. It has the features of good sealing, no pollution, and no need package. To maximum expand the capacity, the cross section is designed to be a large tubular shape with 70 tons loading weight and this structure could disperse the force generated by the collision of bulk grains during transportation, so that the grains should not easily hardened and damp. The loading ports are fitted on the top and the 4 unloading hopper ports are fitted at the bottom. The doors could be operated easily. The bulk grains could flow out automatically by its own gravity. The unloaded grains from the hopper car can be transported to the granary through the conveyor belts under the iron mesh for subsequent processing.

2. Main structures

The grain hopper wagon adopts a complete welded steel loading structure without a center beam, mainly composed of the vehicle body, braking device, coupler buffer device, bogie, and other parts.

-

Wagon body

The vehicle body is composed of under frame, side walls, end walls, funnels, roof, loading port covers, bottom doors, etc. The main structure of the vehicle body is made of Q450NQR1 high-strength weather resistant steel that meets the requirements of Chinese railway.

- Funnels:

- Loading port covers:

- Bottom doors

-

Air brake device

-

Hand brake machine

-

Coupler & buffer

-

Bogie

The bogie adopts K6 type cast steel three piece wagon bogie with a 23.5t axle load. The bolster and side frame are made of B-grade steel with a wide guide frame structure for the side. There is a cross support device between the two side frames. The bolster spring is of two-level rigidity.

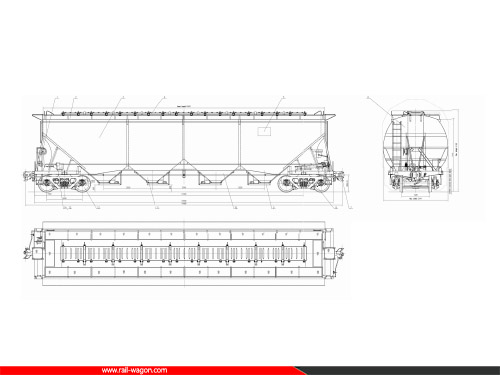

3. Main technical parameters:

Pay load

69t

Axle load

23t

Max. capacity

102m³

Commercial operation speed

120 km/h

Rail gauge

1435 mm

Min radius

145 m

Length

16466 mm

Max. width

3344 mm

Max. Height (empty)

4195 mm

Bogie type

K6 casting bogie

Fixed distance of bogie center

1830mm

Coupler and buffer

No.17 coupler, MT-2 buffer

Coupler center height

880mm

Loading port sizes(length*width)

12620*600mm

Unloading port size(length*width)

800*400mm

Funnel plate inclination

40°(longitudinal)42°(transverse)

Lifespan

25 years

Limit Gauge

Comply with Comply GB146 1-83 ‘standard

gauge railway rolling stock gauge

4. Drawing

5. Detail Photo:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431