KZ70 Ballast Hopper Wagon 70T Ballast Railway Wagon 1435mm Standard Gauge

- Category: Railway Hopper Wagon

- Model: KZ70

- Pay Load: 70 tons

- Volume: 42m³

- Bottom doors opening ≥190m

KZ70 Ballast Hopper Wagon 70T Ballast Railway Wagon 1435mm Standard Gauge

1. Application

KZ70 Ballast hopper wagon is designed for Chinese 1435mm standard gauge railway. It is mainly used to transport bulk goods like ballast during the construction of new railway or repair period of railways.

The wagon could be loaded from the top and unloaded from both bottom and two sides to adapt the operation requirement of railway ballast. The door’s mechanical transmission mechanism adopt pneumatic mainly, supplemented by manual. The unloading of ballast from two sides could be operated separately or together.

2. Main structures

The ballast wagon mainly consists of wagon body, ballast unloading system, coupler buffer device, braking device, and bogies.

-

Wagon body

The wagon body is a welded steel structure without a center beam, consisting of chassis, side walls, end walls, funnels, control rooms, and other parts. The main steel sections and plates are made of Q450NQR1 high-strength weathering steel. The operation cab is a circular arc top all steel welded structure, with inner walls lined with flame retardant insulation materials and flame retardant decorative panels. Equipped with side doors, movable side windows, etc., with safety chains installed outside the side doors. There is an end door at the end。

- Unloading system

The unloading system consists of an unloading door, a pneumatic control system, a manual control system, etc. The pneumatic and manual systems are operated separately. The vehicle is equipped with six unloading doors, two on each side of the vehicle body and two in the middle; The pneumatic control system consists of a control valve, 254 × The 220 rotary bidirectional air cylinder, air supply adjustment valve, combined dust collector, and pipeline are composed, and the wind control pipeline adopts a compression type quick installation pipe joint that meets the requirements of Document No. 10 [2004] of the transportation and loading truck; The manual operation system consists of a new type of reducer, clutch, hollow transmission shaft, and pull rod. The manual operation controls the unloading doors on both sides separately, without controlling the middle unloading door. The unloading system is equipped with anti misrotation devices.

-

Air brake device

-

Hand brake machine

-

Coupler & buffer

-

Bogie

The bogie adopts K6 type cast steel three piece wagon bogie with a 23.5t axle load. The bolster and side frame are made of B-grade steel with a wide guide frame structure for the side. There is a cross support device between the two side frames. The bolster spring is of two-level rigidity.

3. Main technical parameters:

Load

70t

Tare weight

≤23.8 t

Capacity

42 m3

Axle load

23t

Gauge

1435mm

Coupler type

#17 Grade

E Steel

Coupler center height(empty)

880 mm

Length

12074 mm

Bogie type

K6 three big piece casting steel bogie

Fixed axle distance

1830mm

Wheel diameter

840mm

Load method

Upper load, bottom and sides unload

Number of unloading hatch

6

Bottom door length

2236mm

Bottom door opening degree

≥190mm

The min height of hopper bottom(empty)

170mm

End wall inclination

36.5°

Brake method

Air brake

Brake distance

≤1400 m

Brake ratio

7.8

Transmission type

Mainly pneumatic, supplemented by manual

Max. running speed

120 km/h

Min radius

145m

Lifespan

25 years

Limit gauge

Comply with Comply GB146 1-83 ‘standard

gauge railway rolling stock gauge’

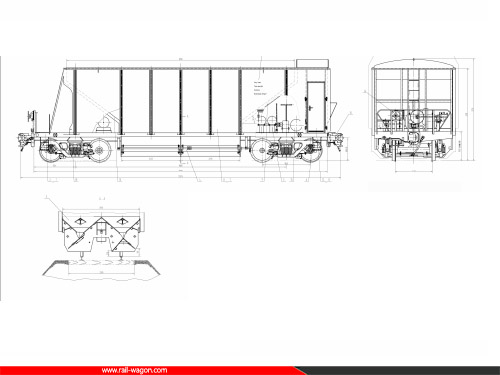

4. Drawing

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431