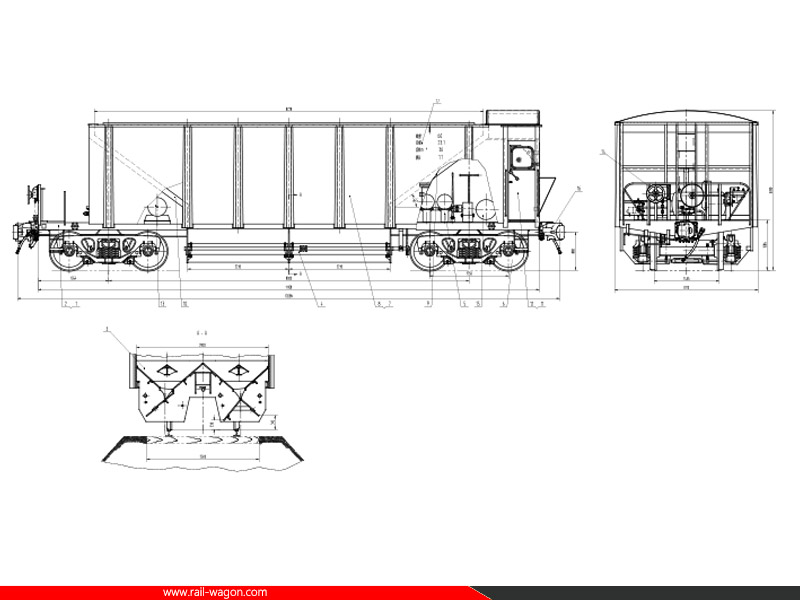

K13 Railway Ballast Hopper Wagon Ballast Transport Hopper Wagon 60T Pay Load

- Category: Railway Hopper Wagon

- Model: K13

- Pay Load: 60 Tons

- Number of hopper doors:6

- Discharge method: by air, assisted by manual

K13 Railway Ballast Hopper Wagon Ballast Transport Hopper Wagon 60T Pay Load

1. Application

K13 Ballast hopper wagon is a special railway hopper wagon to transport stone slag for laying ballast of new or old railway, or to transport similar grain goods for industrial or mineral factories. It could be loaded from both sides of the railway. When unloading the ballast, the bottom doors could be operated pneumatically or by manual.

2. Main structures

The ballast hopper wagon is mainly composed of wagon body, ballast discharge system, coupler & buffer device, brake device, bogies and etc.

-

Wagon body

The wagon body is all welded structure without center beam, consisting of a chassis, side walls, end walls, funnels, and other parts.

- Ballast discharge system:

-

Air brake device

-

Hand brake machine

-

Coupler & buffer

-

Bogie

It adopts K2 type 3 piece casting bogie.

The material of bolster and side frame is B-grade cast steel. The main friction plate of the composite wedge is made of polymer composite material, and the wedge body is made of bainitic ductile iron. The material of the side frame column wear plate is 45 steel, and the sliding groove wear plate is T10. The bogie adopts two-stage stiffness springs. Using a lower center disk plate with a diameter of φ 355mm, the lower center disk is equipped with a conductive center plate wear disc. It installs 197726 compact bearings, RD2 axles, and LM wear type tread HDZB cast steel, HDSA rolled steel wheels. The basic braking device adopts an austenitic ductile iron lining and a combined braking beam. The braking beam frame is connected to the brake shoe support with steel rivets.

3. Main technical parameters:

Load

60t

Tare weight

≤23t

Capacity

36 m3

Axle load

21t

Gauge

1435mm

Coupler type

#13

Coupler center height(empty)

880 mm

Length

12038mm

Bogie type

K2 Bogie

Fixed axle distance

1750mm

Wheel diameter

840mm

Load method

Upper load, two sides and bottom

pneumatic unloading

Number of bottom doors

6

Bottom door length

2235mm

Bottom door opening

≥190mm

Ballast guiding plate min height to

rail(empty)

310mm(side), 230mm(middle)

Funnel min height to rail(empty)

170mm

End wall slope

36.5°

Brake method

Air brake

Brake distance

≤1400 m

Brake ratio

9.6

Max. running speed

120 km/h

Min radius

145m

Lifespan

25 years

Limit gauge

Comply with Comply GB146 1-83 ‘standard

gauge railway rolling stock gauge’

4. Drawing:

5. Detail photo:

6. Video of K13 ballast wagon:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431