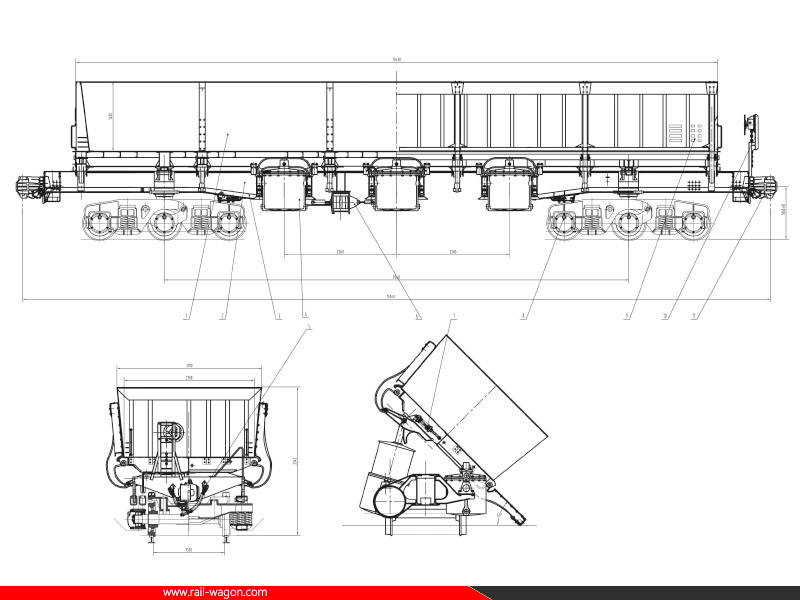

1520mm Gauge Railway Side Dump Wagon 105t for Ore, Coal, Steel Slag

- Category: Railway Side Dump Wagon

- Model: KF105

- Pay Load: 105 tons

- Rail gauge: 1520mm

- Carriage overturn angle: 45°

1520mm Gauge Railway Side Dump Wagon 105t for Ore, Coal, Steel Slag

1. Application

The broad gauge side dump car is a bi-directional pneumatic tipping and unloading vehicle running on railway of 1520mm gauge. It is suitable for factories, mines, and large construction sites with mechanized loading equipment. It can be used to transport relatively heavy bulk cargoes such as ore, glass rock, gravel, coal, building materials, etc.

2. Main structures

The car body is of all steel riveted welding structure. The whole car is composed of under frame, carriage, tipping cylinder, tipping pipeline, side door opening and closing device, air brake device, coupler buffer device, bogie, etc.

-

Under frame

The under frame is of all steel welding structure, which is composed of end beam, middle beam, sleeper beam, etc. The end beam is formed by pressing 8MM plates; the center beam consists of two H-shaped steels, upper and lower cover plates and diaphragms to form a box shaped fish belly structure. The center beam, end beam and sleeper beam form the main structure. Tipping cylinder frame, square support, “Y” shaped support and other accessories for installing brake and tipping pipeline are assembled and welded on both sides of the under frame’s center beam.

-

Carriage

The carriage is composed of carriage underframe, side doors and end walls. The carriage underframe is composed of end beam, center beam, side beam, cross beam, and running beam. The end beam is a profiled structure, the center beam is an I-beam, and the running beam is a channel steel. The side door consists of side door hinge, side door panel and side pillar. The end wall is composed of end column, corner column, upper eave beam of end wall and end wall plate.

- Tilting device

The tilting device mainly consists of tilting pipeline system, tilting cylinders, door leaf suppression and other parts.

-

Tilting pipeline system

The tilting pipeline system consists of an air storage cylinder and various valves. This system is the operating system for tilting and unloading the carriage. By operating the valves, compressed air enters the tilting cylinders to lift the carriage for tilting and unloading.

-

Tilting cylinders

The tilting cylinder adopts a two-stage piston structure, consisting of inner and outer pistons, piston rod tilting cylinder jacket, top iron, etc. The cast iron inner and outer pistons are sealed with rubber cups and pressure rings.

-

Door leaf suppression

Door leaf suppression is composed of suppression elbows, suppression springs, rollers, etc. It is a follow-up mechanism that controls the opening and closing of side doors, directly determining the vehicle's tilting ability.

-

Air brake device

-

Hand brake machine

-

Coupler & buffer

-

Bogie

It adopts self-developed 1520mm gauge 3 axle casting bogie.

3. Main technical parameters:

Load

105t

Tare weight

≤54.5 t

Capacity

50 m3

Axle load

30t

Gauge

1520mm

Coupler type

CA-3

Coupler center height(empty)

1060 mm

Length

15040 mm

Bogie type

1520mm gauge 3 axle Bogie

Fixed axle distance

1300mm

Wheel diameter

957mm

Load method

Upper load, two sides air tipping

unloading

Cylinders qty

6

Side wall tipping degree

45°

Brake method

Air brake

Max. running speed

80 km/h

Min radius

80m

Lifespan

25 years

Limit gauge

Comply with ГОСТ 1-T of 9238-83 standard

Load

105t

Tare weight

≤54.5 t

Capacity

50 m3

Axle load

30t

Gauge

1520mm

Coupler type

CA-3

Coupler center height(empty)

1060 mm

Length

15040 mm

Bogie type

1520mm gauge 3 axle Bogie

Fixed axle distance

1300mm

Wheel diameter

957mm

Load method

Upper load, two sides air tipping unloading

Cylinders qty

6

Side wall tipping degree

45°

Brake method

Air brake

Max. running speed

80 km/h

Min radius

80m

Lifespan

25 years

Limit gauge

Comply with ГОСТ 1-T of 9238-83 standard

4. Drawing

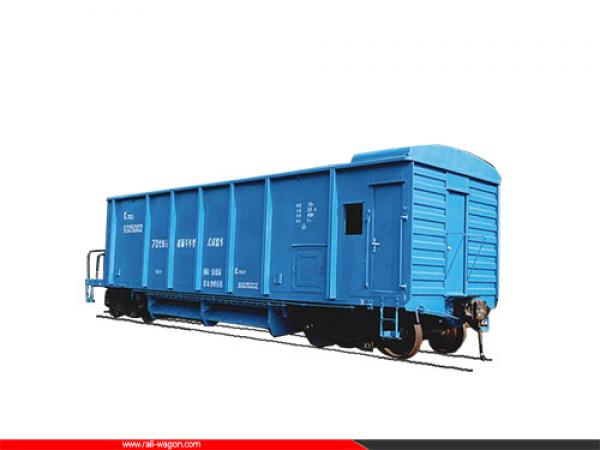

5. Detail Photos

6. Videos of side dump wagon:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431